About Us

Go with the flow

As a high-end men’s shoe brand, Phoebe Graham’s goal is not luxury, but the ultimate quality in craftsmanship, skills, engineering, materials and design. With roots in both large-scale shoemaking and artisan tradition, Phoebe Graham found a suitable production partner in the Veneto region in northern Italy.

As Austrians, we value effortless understatement and the simple, beautiful things in life, and we believe that Phoebe Graham’s understated style is easily recognized by anyone, anywhere, who values beauty and quality.

Further changes

We share the Venetian passion for all things new and beautiful, but also a deep appreciation for craftsmanship and lifestyle traditions.

Phoebe Graham's decoration is minimal and the shapes are extreme. The last and materials are carefully considered. The formula may seem simple, but these materials require exquisite craftsmanship to create an extraordinary pair of shoes.

Restoring the classics

Phoebe Graham's shoes are made by more than 300 craftsmen, some of whom have been in the business for 40 years, and others are younger. Their combined experience is hundreds of years of shoemaking experience. This is the essence of our heritage.

In 2008, Phoebe Graham joined the company as a partner and took over management.

After studying shoemaking in London, he developed a strong interest in craftsmanship and men's shoes. Phoebe Graham proposed the slogan "Restore the essence" and launched the sub-brand Maden, which reproduces military training shoes from the 1950s to the 1990s. The design inspiration of each series is drawn from the military shoes of various European countries from the 1950s to the 1990s, and they are reshaped with a strong retro style.

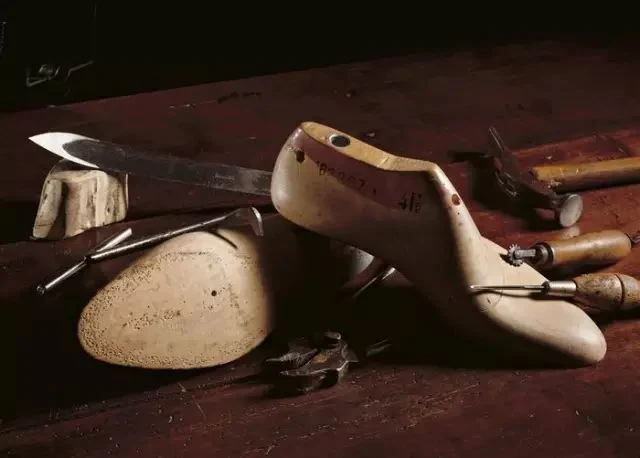

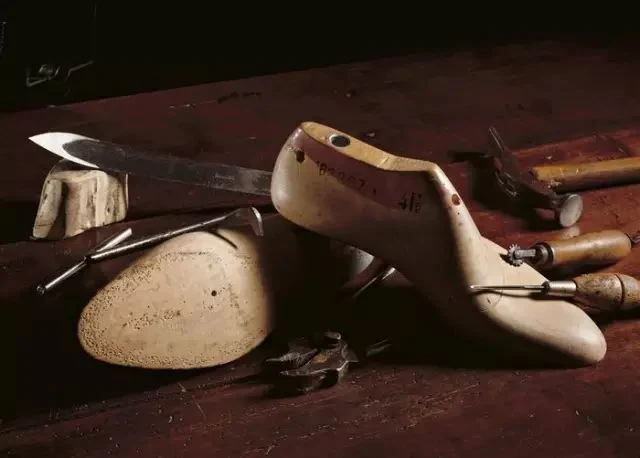

Craftsmanship

Most of our shoes made from high-tech synthetic materials are designed by computer and manufactured by robots. We still draw our models in pencil on lasts. Our handmade products require hundreds of steps by skilled craftsmen to complete a pair of shoes.

Many steps are completed with simple hand tools, such as hammering, hand-sewing the welt or bottoming the moccasin. Other steps use heavy and sometimes dangerous mechanical equipment; but always under the guidance of skilled craftsmen to ensure the perfect final product.

One more thing

Always be with customers - learn more about them.

We respect customers' opinions, which is the source of our continuous improvement. Customers' real feedback on boots will be directly applied to the design, production and transportation of boots. This is a virtuous circle that drives us to make continuous progress.

Through customers' evaluation of products, we will seriously consider the core intention of feedback, which will also serve as an important basis for our development of new products. We welcome customers to communicate with us through email, social media, WhatsApp, etc., and any problems will be solved sincerely and effectively.